Engine health

by

PostedA couple of weeks ago I had the Grob in for a 1000 hour inspection, and I took the opportunity to get my borescope into the engine’s cylinders and have a look at the state of the exhaust valves, and take some pictures of them.

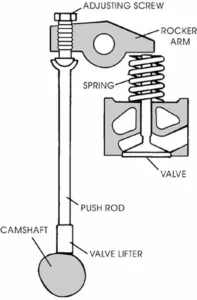

The valves sit in the cylinder head and are pushed open by the cams on the camshaft via the pushrod and rocker arm. The exhaust valve is the one in each cylinder that opens to let the burnt (and sometimes still burning) fuel air mixture out through the exhaust as the piston comes back up during the exhaust stroke.

Here’s a diagram of a typical overhead valve engine, showing how the cam manages to open the valves:

Because the gas going past the exhaust valve head is tremendously hot, the exhaust valve soaks up a lot of heat during the period that it’s open. The valve is cooled via two paths, firstly down the valve stem and out through the valve guide, and secondly out the edge of the valve head into the valve seat during the time the valve is shut. That requires the edge of the valve to re-seat properly against the valve seat in the cylinder head every cycle. So when the engine is overhauled it’s an important and time-consuming preparatory task to lap the valve and seat together with fine grinding paste to make sure the contact surfaces are polished and smooth and in good contact. If that’s not done properly, or if any residue gets stuck on the valve seat during engine operation, the valve doesn’t close properly, the heat absorbed from the exhaust gas can’t escape, and the head will get too hot.

A valve head that gets too hot has a tendency to crack, and eventually the crack will extend, which means a further barrier to heat loss, and more overheating, and more cracking, until eventually a piece of the edge of the valve head breaks right off into the cylinder. That means a sudden and significant loss of power due to a lack of compression on that cylinder, and having a piece of metal valve head bouncing around inside the engine as you fly along. Cue a likely emergency landing in a field somewhere. Not good.

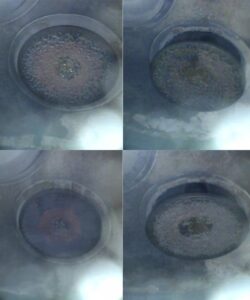

So it’s not a bad idea every now and then for an owner to take a look at the faces and edges of the exhaust valves to see if there’s any evidence of cracking or, prior to that, any evidence of the valve not seating properly. If the valve is seating correctly you expect to see a bullseye pattern on the valve head indicating a symmetrical temperature distribution with heat being conducted equally in all directions out to the edge. If you see a lopsided pattern then you can tell one part of the edge of the valve is getting hotter than the rest, and cracks are more likely to occur there.

Here are the pictures I snapped of the valve faces, showing nice symmetric heat patterns, suggesting good valve seating and symmetric heat conduction:

By way of comparison, here’s the valve face from a different engine, where you can see the lopsided heat pattern. This is definitely one to watch, with a possibilty of valve cracking in the not too distant future:

There are various different mechanical defects that can occur in an engine during flight, all of them rare, but some less rare than others, and most of them are hard to predict. But in this instance I was happy to be able to confirm visually that the valves in FLYO’s engine aren’t in bad shape at the moment.